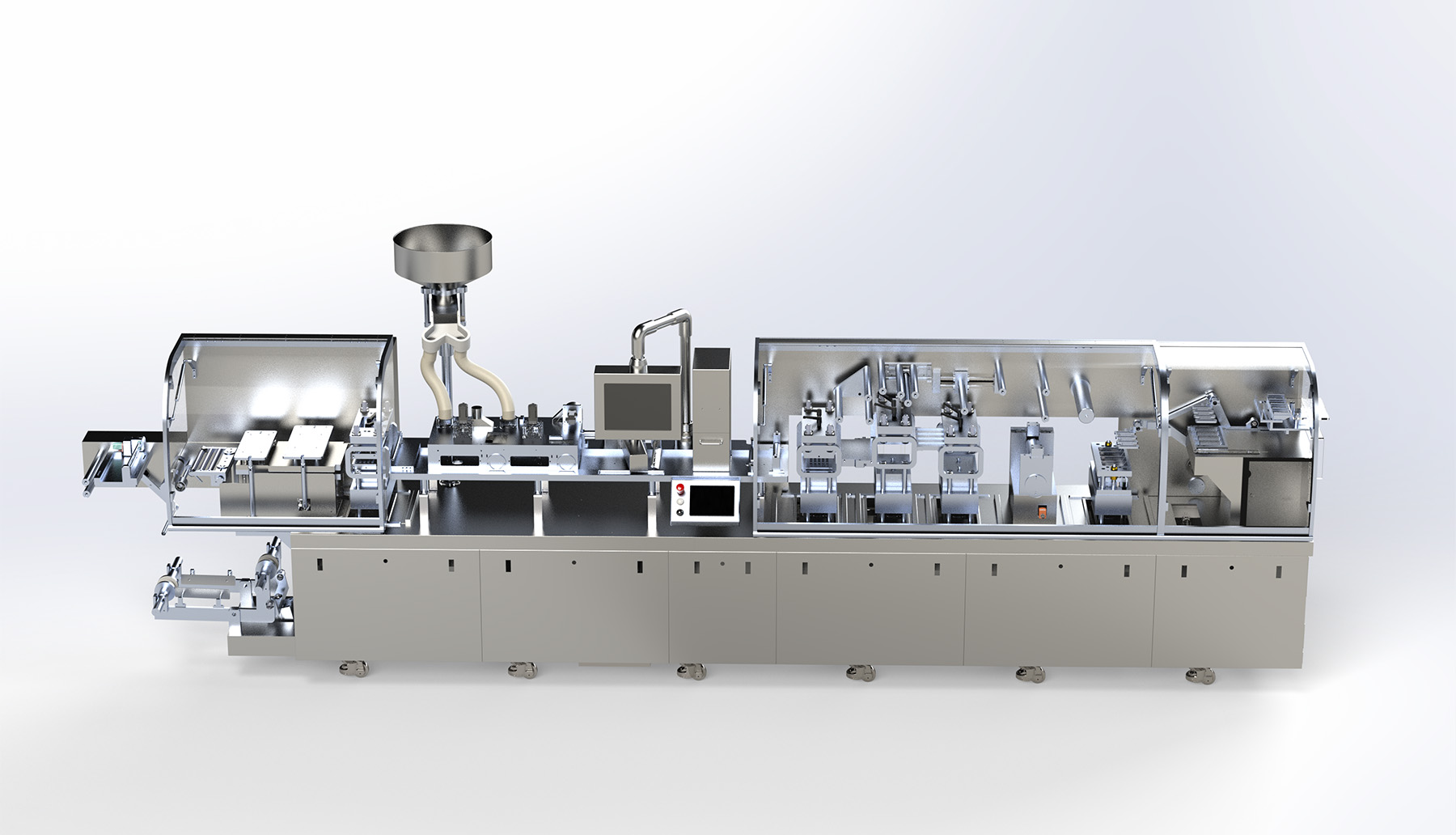

Pioneering Dynamic Solutions on packaging lines

Toolrite design, manufacture and build precision engineered GMP compliant tooling and spares, in combination with process & packaging solutions for pharmaceutical, nutraceutical and subsidiary industries.

Toolrite offer precision solutions to maintain and increase the productivity of our customers’ packaging lines. From maintenance and repairs of bespoke items to complete tooling sets; all designed, manufactured and built in-house. Our industry knowledge allows us to optimise packaging lines on all leading Original Equipment Manufacturers (OEM’s).

Pioneering Dynamic Packaging Lines

The ‘’beating heart’’ of our company is our in-house design team, many of whom have honed their skills as toolmakers and precision engineers at Toolrite.

Delivering Increased Overall Equipment Effectiveness

Our process experience is crucial to the design of components, packaging formats and operational effectiveness.

High Tech In-house Capabilities

Continued investment in the latest machinery and design software technologies allowing us to effectively support the industry in a timely and cost-effective manner.

Testing & Development

Testing and development is key to providing first time right solutions. A range of testing equipment is on hand to support blister tooling, prototyping, feed design and development ensuring your product works first time.

Support & Service Support

On-site support, maintenance, upgrades, installation and validation guidance.

Compliance & Traceability

We provide compliance documentation ensuring all goods supplied meet operational and regulatory demands.

Toolrite offer precision solutions to maintain and increase the productivity of our customers’ packaging lines.

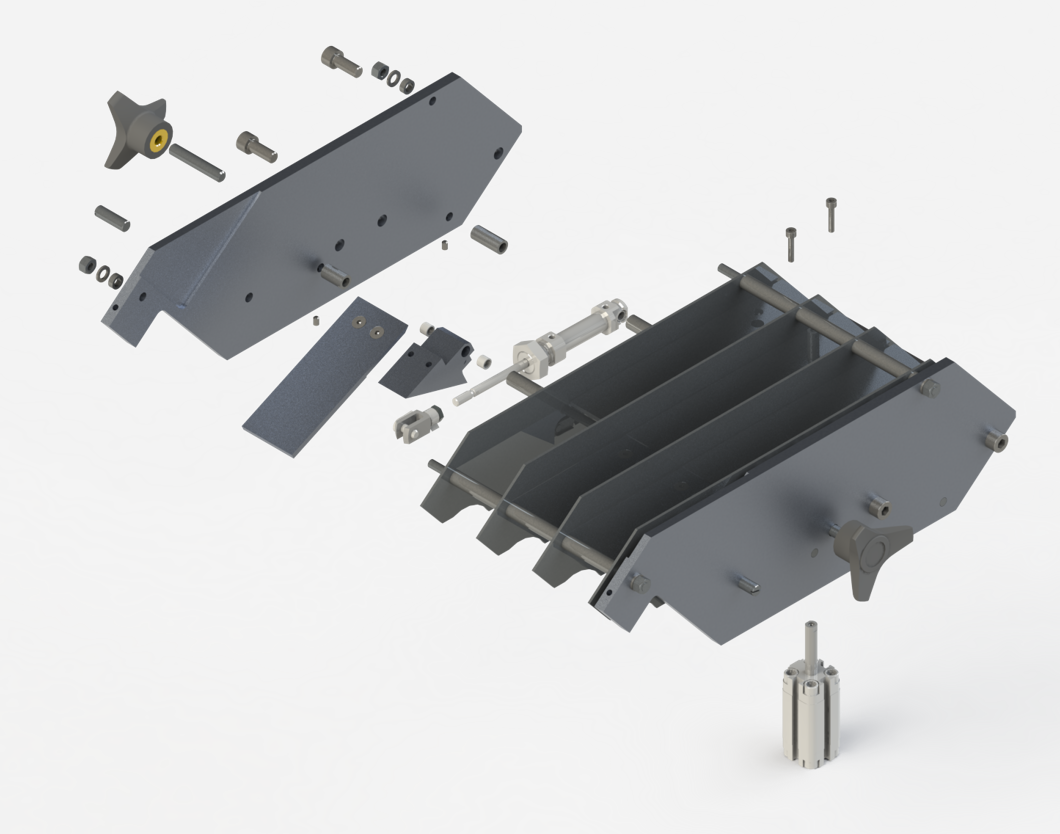

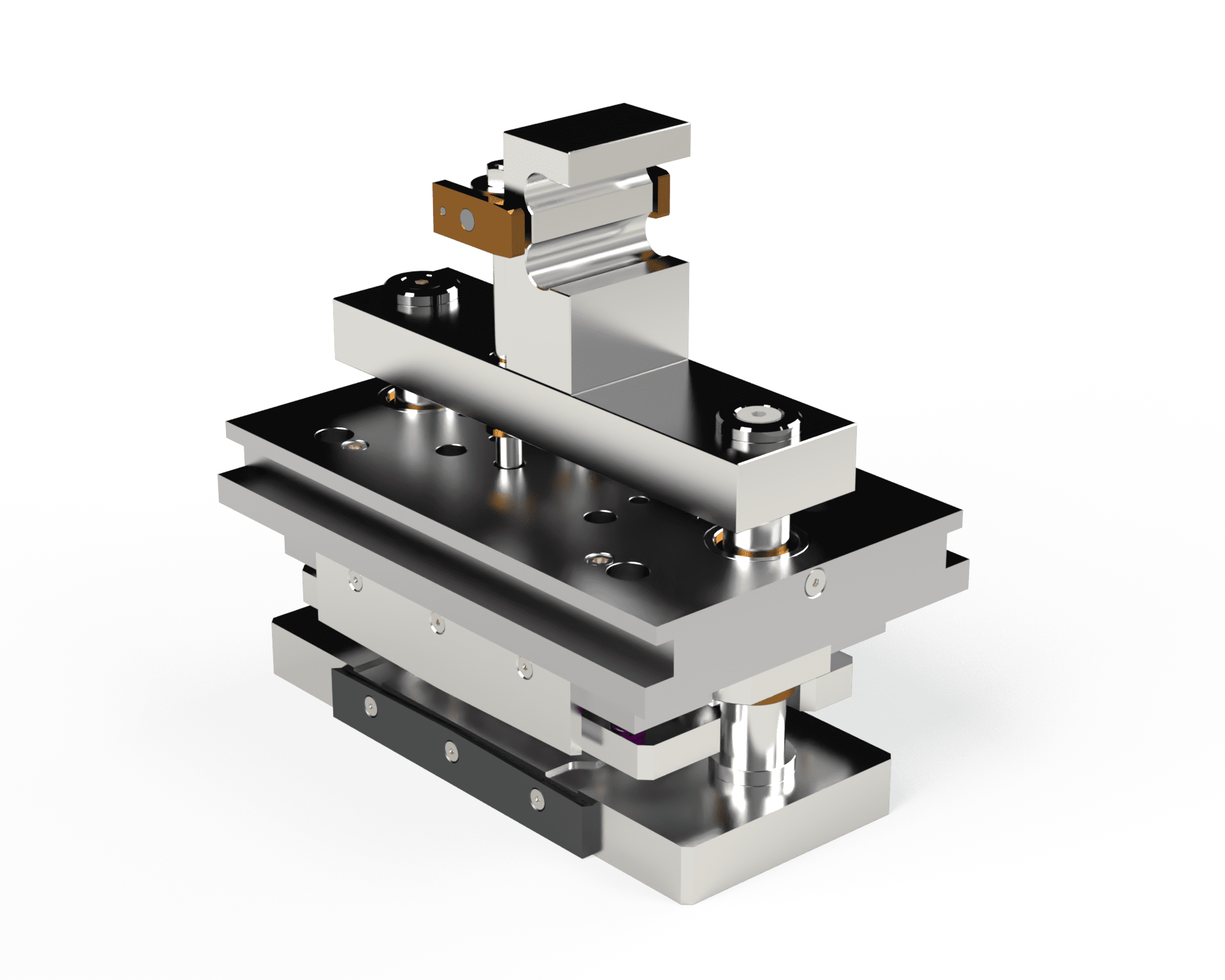

Function: A form tool transforms a flat material into a three-dimensional tray, designed to hold the product in a ‘pocket’ through the packaging line until it becomes an enclosed pack.

Toolrite Offering: Packs are designed, not only to securely protect and hold a product, but also to guarantee its formation on the packaging line, in an automated way. Consideration given to forming material, product shape, pocket dimension, repeats and pack layout. We can provide forming tools to accommodate a variety of products to meet your needs.

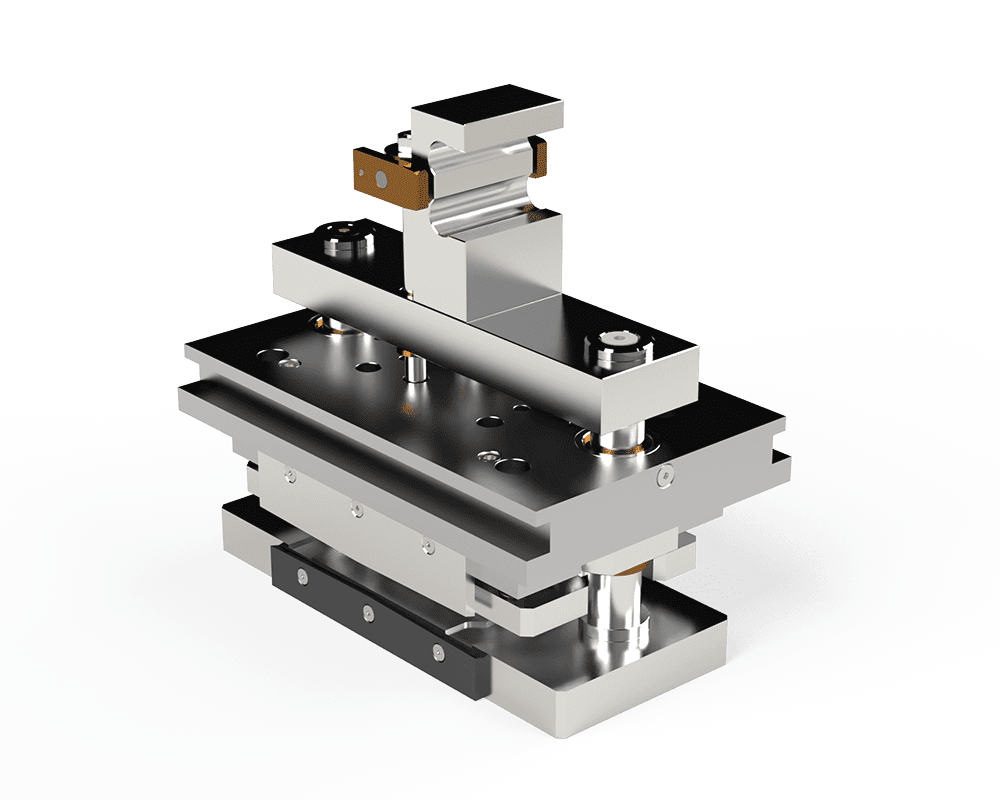

Function: The sealing station brings together the filled form material, together with the foil where a combination of heat and pressure is used to seal the materials together. After the sealing process is complete, the product is safely secured in the pack and can continue its journey down the line.

Toolrite Offering: By utilise intermittent motion platen sealing or continuous motion rotatory sealing we can provide appropriate sealing tools for your packaging line.

Function: The Blank tool is used to cut a pack to its final dimensions.

Toolrite Offering: We design and manufacture Blank tools when there is product changeover and/or format changes.

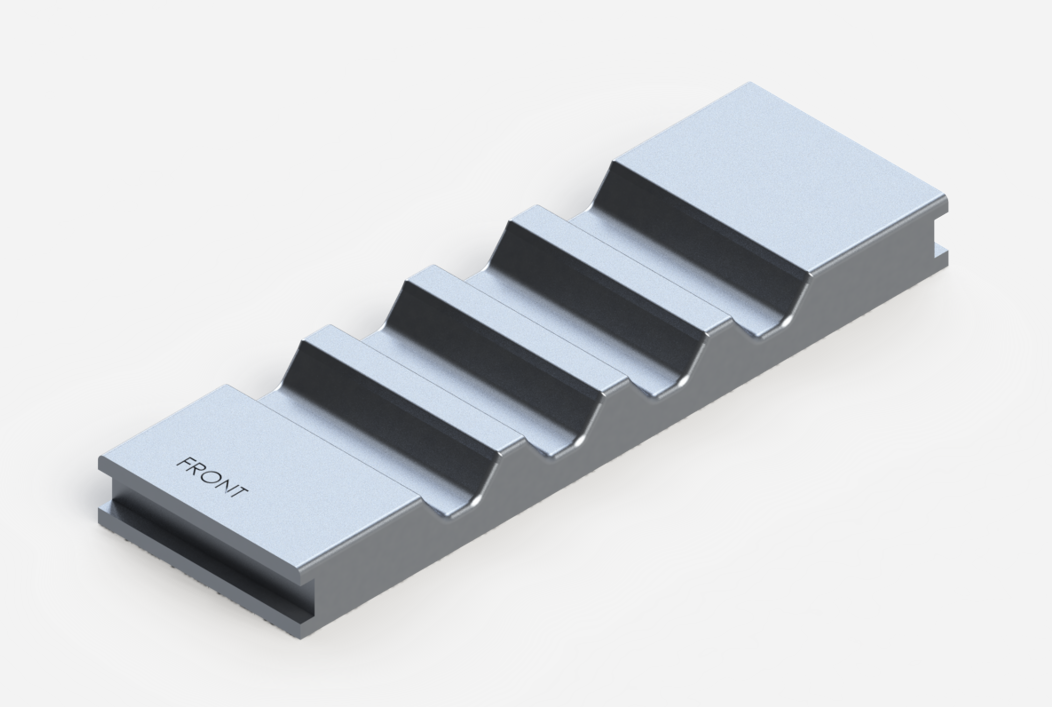

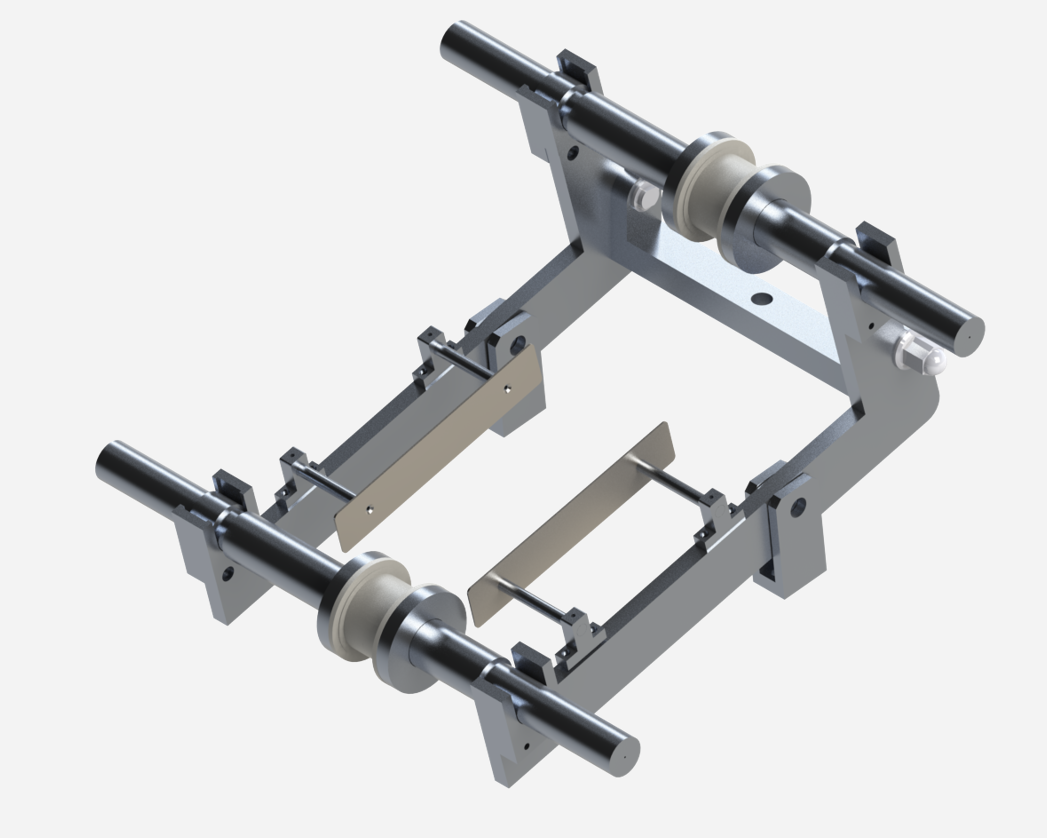

Function: As the name suggests, the track guides the form material keeping it located, aligned, and supported enroute to the various stations. The guide track design is based on the pack design, so if this changes, the guide track will also require modification.

Toolrite Offering: This is a standard modification due to clients requiring product changeovers and alterations to pocket formats. 90% of the time guide tracks are usually just one component in a complete tooling set.

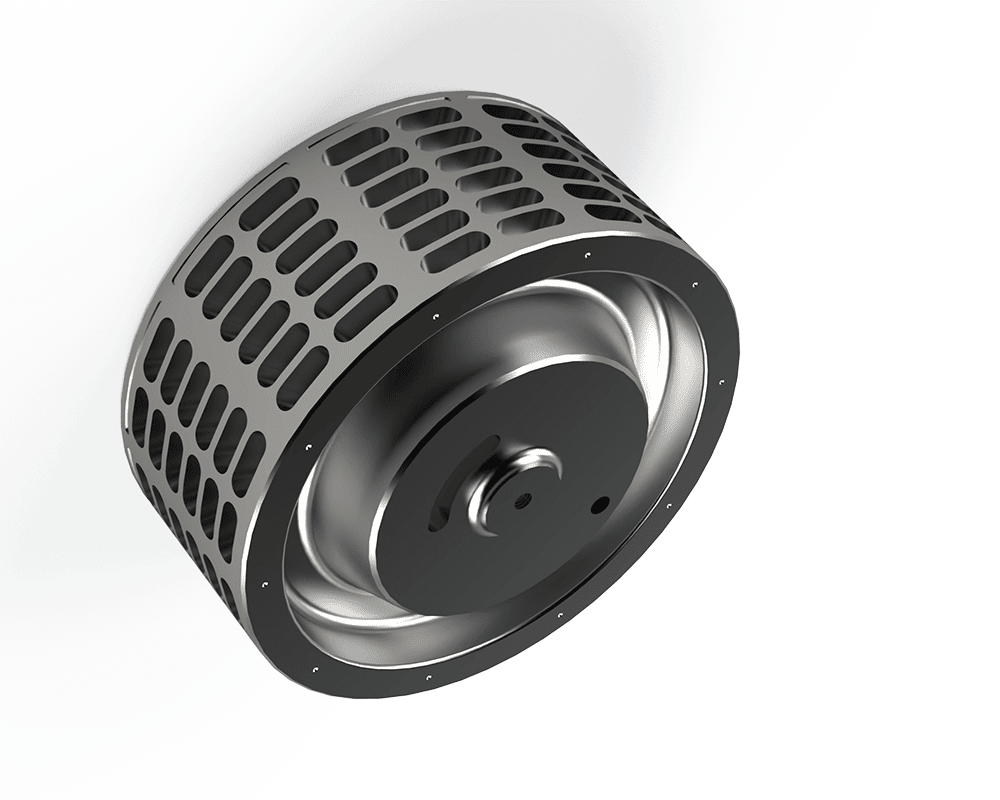

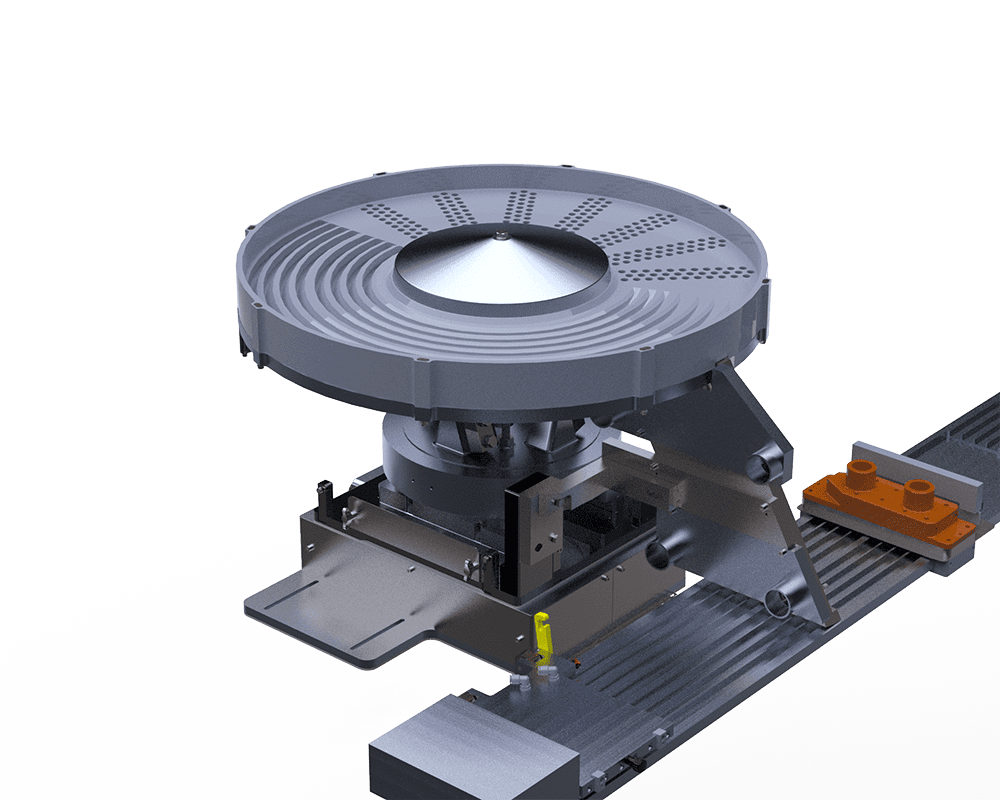

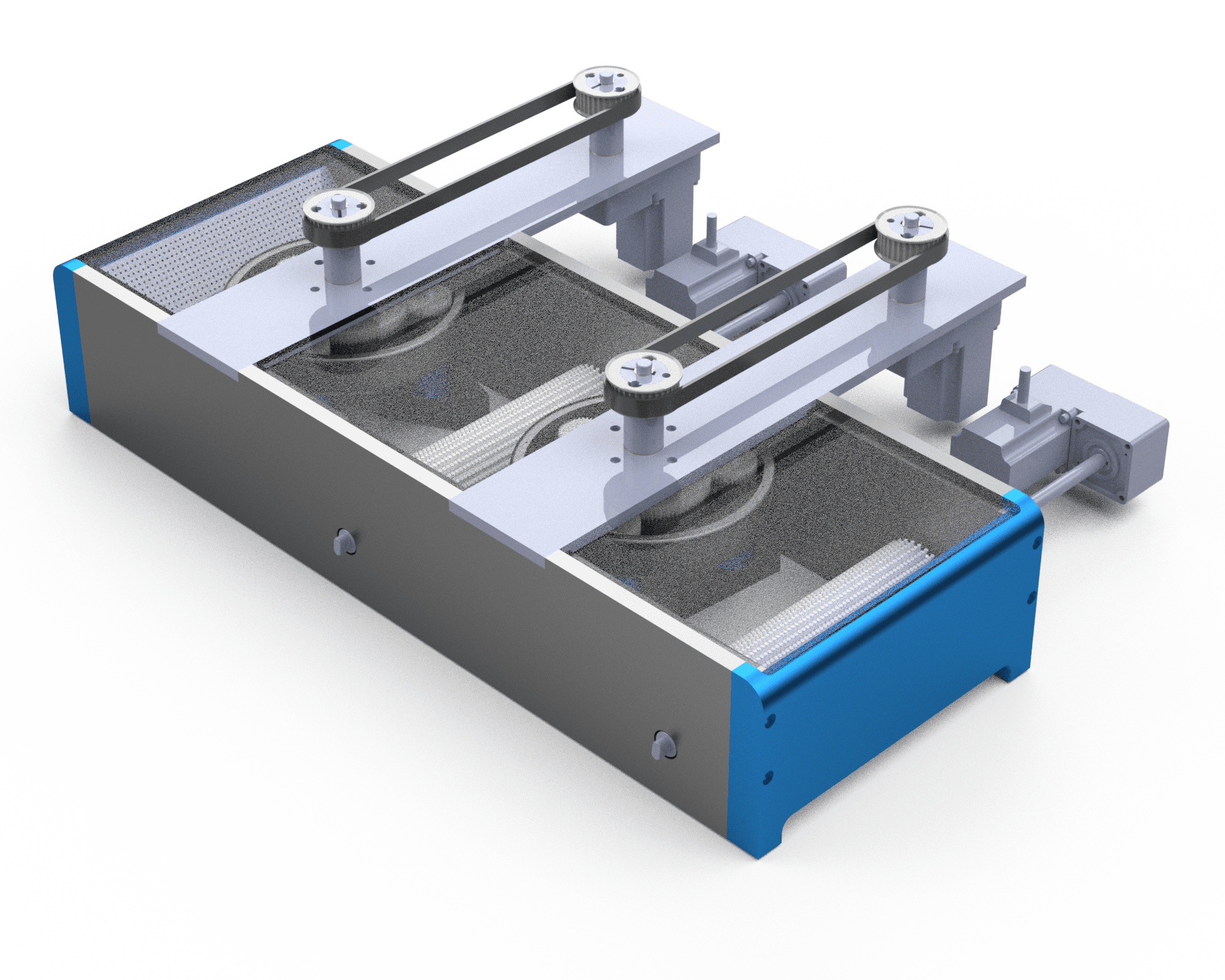

Function: Here the product is introduced into the line for the first time. It is held in the hopper and passed into the vibratory chute separating dust and debris. Then into the vibrator plate of the circular vibrator, where they are transported into the feed chute and eventually into the feeding system.

Toolrite Offering: We can design and manufacture a new solution, or adapt an existing set up, for your product changeover so it is managed and then delivered to the feeding system in an automated and reliable way.

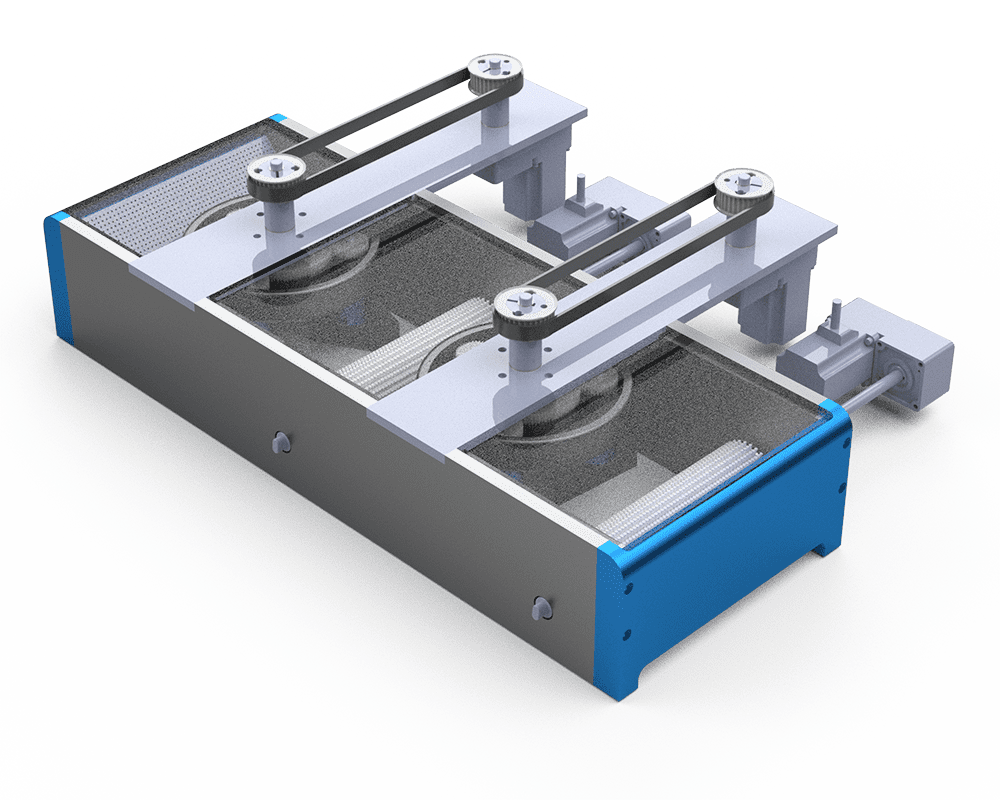

Function: Once the product is delivered from the transfer system it needs to be manipulated into the formed pockets. This is done using a brush box and in some cases paddles too.

Toolrite Offering: Designing and manufacturing the feeding system is a critical part of any packaging line. It determines the output speed and the efficiency of a line. Toolrite will help you choose the right solution for your product so cost effective and efficient production is achieved.

Function: The Reject unit is used to separate faulty packs.

Toolrite Offering: We design and manufacture these units to your specification.

Function: Additional stations can be setup using tools to; code, perforate or partially cut.

Toolrite Offering: We can apply unique identifier codes, perforate, and other pack features such as partial cutting or punch shapes as required.

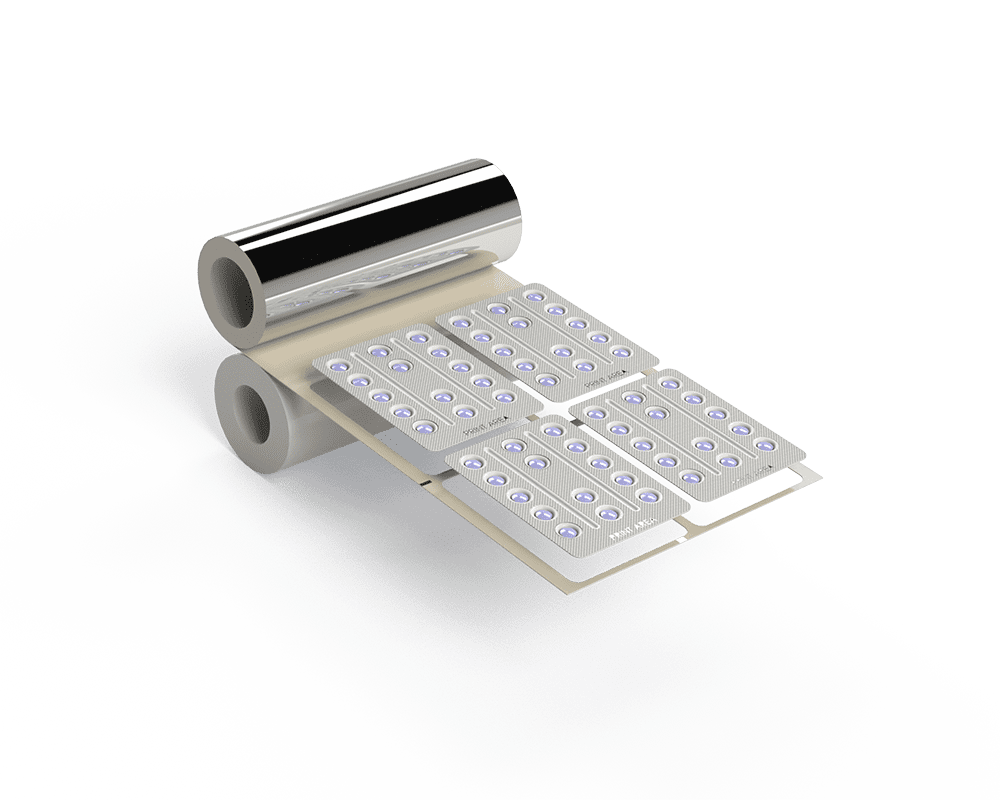

Function: Forming material is loaded as a reel/roll into the unwinder. So that the film can be used, it needs to be unrolled and prepared for the forming tool. To do this the material is under tension and pulled through the packing line.

Toolrite Offering: Design and supply collars/ sleeves so the material core fits well, ensuring reliable unwinding of the form material into the packaging line.

Function: Cutting and splicing table alterations ensure the base material is prepared and cut prior to conditioning in preparation for the form tool station.

Toolrite Offering: Review and design alteration to allow setting adjustment.

Function: These plates thermally condition the form material prior to its entry into a form or sealing unit.

Toolrite Offering: Recondition plates, including recoating to keep them to specification.

Function: The main heat plate ensures the required form temperature is met, so that as it travels into the form tool it is optimised for forming.

Toolrite Offering: CMM for flatness and regrind appropriately for flatness, if possible. Remove worn coatings, pre-treatments, prepare surfaces for recoating.

Alternatively, design and manufacture new plates when there is too much distortion or wear. Pre-treat and coating with different options, e.g. plasma, to keep them to specification.

Function: Perfect forming is enhanced with direct cooling to prevent material distortion and to stabilise width.

Toolrite Offering: Design and manufacture integrated post form chiller and retrospective installation to an existing line. This modification helps to prevent forming issues before you fill and seal.

Function: Solutions designed to provide optical inspection of blister packs ensuring positioning of the packaging, defects of the surface before filling, positioning of the product in the packaging and micro tears of the aluminium foil.

Toolrite Offering: Integration of an inspection system to guarantee integrity of the pack on customer packaging lines.

Function: The pick & place unit is used in the preparation and configuration of finished packs ready to be transferred to the carton packing line.

Toolrite Offering: We design and manufacture Pick & Place tooling to meet your required configuration.

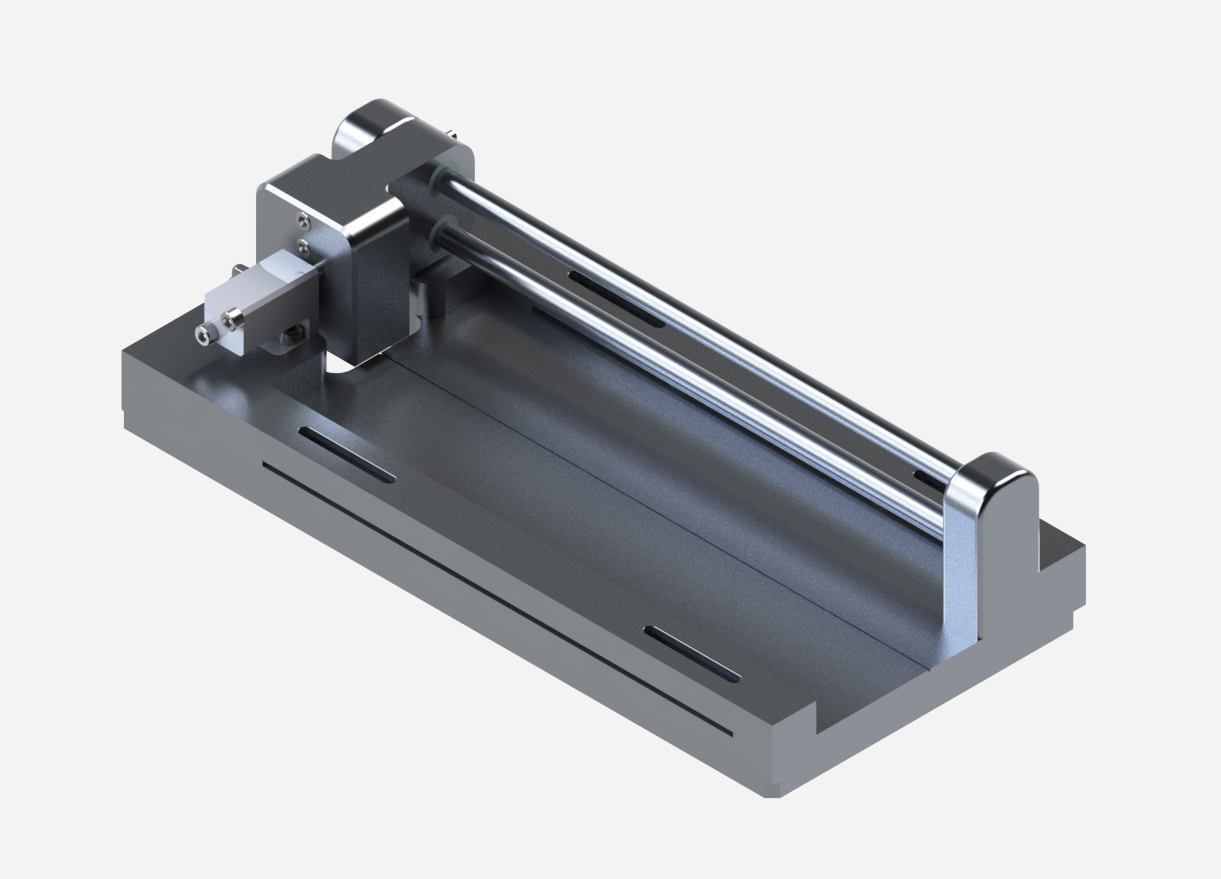

Function: The drive unit determines the travel of material from the Unwind reel through the line to the reject unit.

Toolrite Offering: We refurbish and replace the lower drive roller as well as the upper roller usually due to product changeover and/ or format changes.